Patent US3343828 High vacuum furnace Google Patents

which transferred from the furnace to the chamber wall. 2. Vacuum furnace design and construction Figure 1. shown the systems consist of a chamber that made of cylindrical glass, stainless steel plate (base plate), a cylindrical graphite furnace encircled with the ceramic tube, a graphite support made of

Patent US7204952 Vacuum furnace for carburizing with hydrocarbons Google Patents

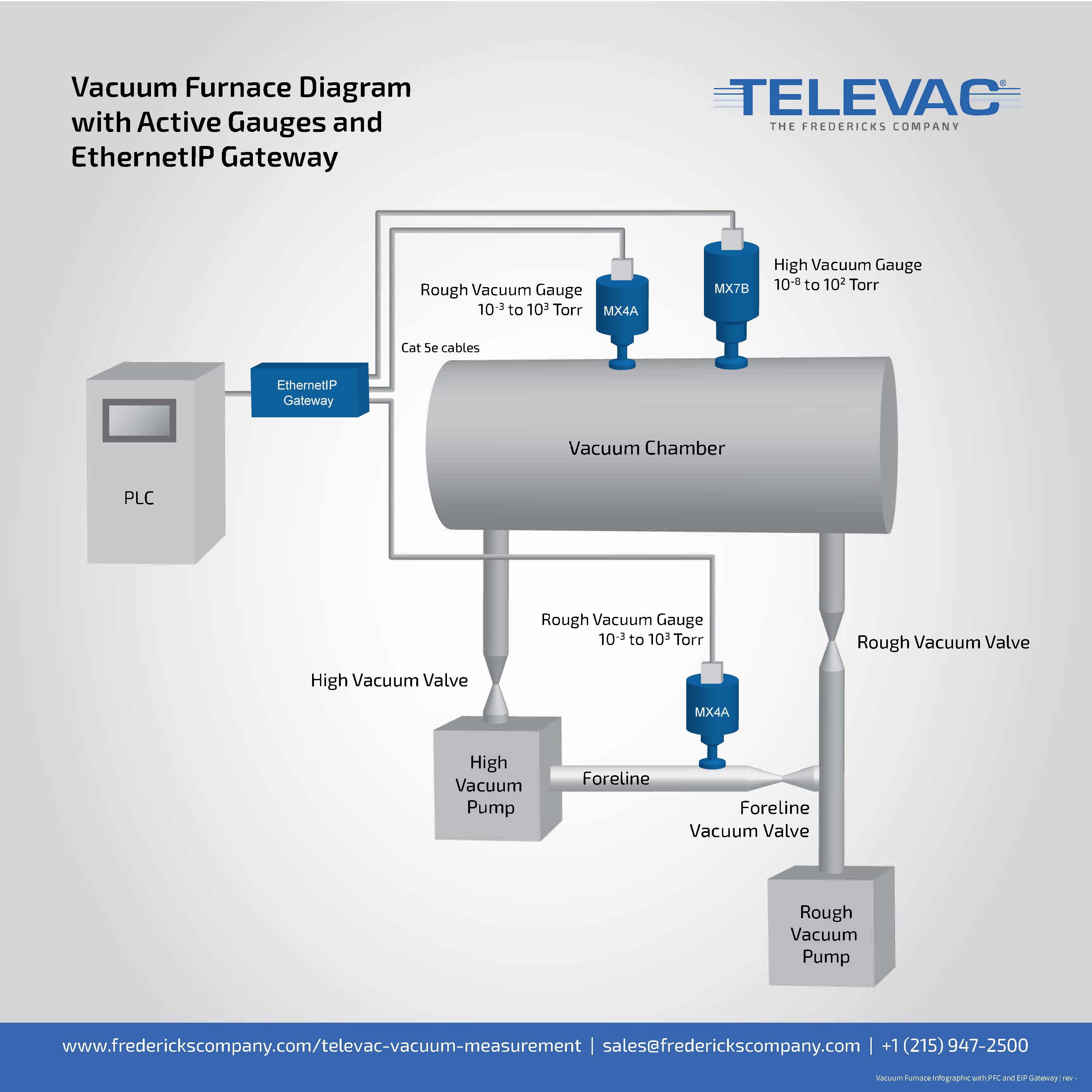

A vacuum furnace refers to the use of vacuum systems (consisting of vacuum pumps, vacuum measuring devices, vacuum valves, etc.) in the specific space of the furnace chamber to remove the air from the furnace chamber so that the pressure in the chamber is less than a standard atmospheric pressure, the space in the furnace chamber to achieve a va.

Vacuum furnace structure, working principle and schematic diagram Brother Furnace

A vacuum is one of the methods to protect heated steel and metal parts from the negative influence of an air atmosphere. A vacuum furnace is normally an electrically heated furnace in which a vacuum is maintained during the process. Most vacuum furnace are heated by electric resistance elements made from graphite, ceramics or metals.

VACUUM FURNACE SYSTEM 동아셀바이오

Download scientific diagram | Schematic model of a vacuum furnace. from publication: Production of magnesium during carbothermal reduction of magnesium oxide by differential condensation of.

Vacuum Furnace System ULVAC (THAILAND) LTD.

A vacuum furnace is a type of furnace in which the product in the furnace is surrounded by a vacuum during processing. The absence of air or other gases prevents oxidation, heat loss from the product through convection, and removes a source of contamination.

The buyer's guide to vacuum furnaces 10 things to know [1/2]

Vacuum furnace structure and schematic diagram PRODUCT CATEGORIES Vacuum Heat Treatment Furnace Horizontal Type Vacuum Gas Quenching Furnace Vertical Type Vacuum Gas Quenching Furnace Dual-Chamber Vacuum Oil Quenching Furnace Dual-chamber Vacuum Gas Quenching Furnace Horizontal Type Vacuum Annealing Furnace Vertical Type Vacuum Annealing Furnace

Conductance & Throughput in Vacuum Pipelines

The vapor pressure of a material is that pressure exerted at a given temperature when a material is in equilibrium with its own vapor. Vapor pressure is a function of both the material and the temperature. Chromium, at 760 torr, has a vapor pressure of ~4,031°F. At 10¯5, the vapor pressure is ~2,201°F.

What’s the vacuum furnacevacuum furnace principle SIMUWU

Hot zone Pumping system Cooling system Control system (temperature & vacuum) Handling system Figure 1 | Typical system components of a bottom loading vacuum furnace2 (courtesy of Eurotherm, A Schneider Electric Company) Vacuum furnaces available from most manufacturers are either horizontal (Fig. 2) or vertical (Fig. 3) configurations.

Patent US6349108 High temperature vacuum furnace Google Patents

A vacuum system (Fig. 1) provides a space in which the pressure can be reduced and held below atmospheric pressure at all times. One of the primary advantages of vacuum heat treatment is its versatility.

Tips for a Healthy Vacuum Furnace System Heat Treat Today

For vacuum furnaces, the heating elements are typically wide strips and ribbon-shaped to maximize both their physical and radiant surface areas. Metallic heating elements for high-temperature vacuum furnaces are commonly made of refractory metals (Fig. 1). Refractory metals are extremely high melting point metals that are resistant to wear.

Patent US4171126 Vacuum furnace with cooling means Google Patents

The overall diagram of the experimental site is shown in Fig. 1. (a), the heating furnace diagram in vacuum furnace is shown in Fig. 2. (b), and the thermometer being measured is shown in Fig. 3. (c). International Conference on Mechanical, Electrical, Electronic Engineering & Science (MEEES 2018)

ItemVF381 TAV Horizontal Vacuum Furnace LOCATED IN THE UK The Monty

Context 1. experiments were carried out in a self-made vacuum furnace shown in Fig.. View in full-text Context 2. reversion reaction ratio (g) was defined as where W 0 represents the.

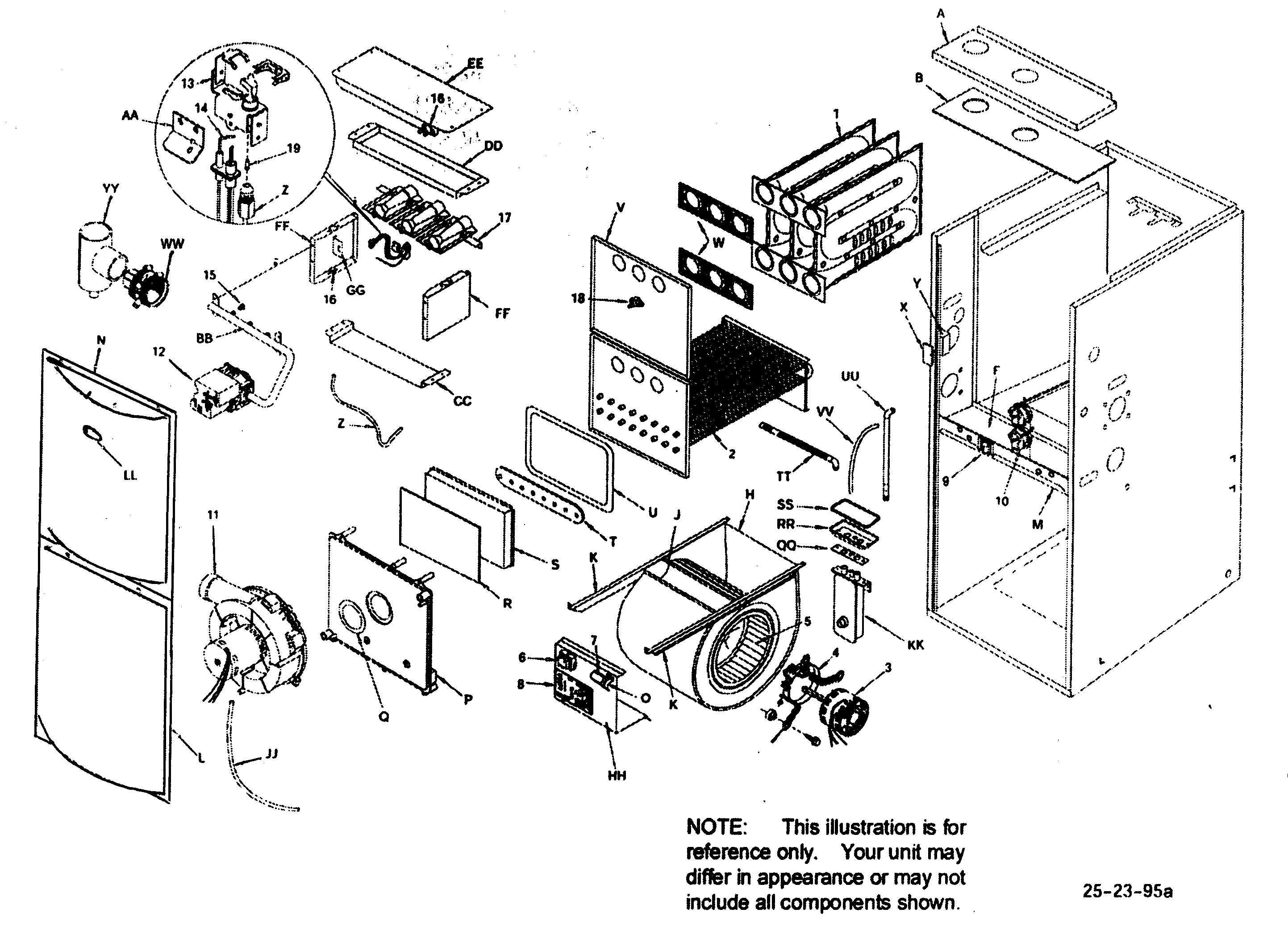

Icp model H9MPD075F12B1 furnace/heater, gas genuine parts

Vacuum heat treating consists of thermally treating metals and alloys in cylindrical steel chambers that have been pumped down to less than normal atmospheric pressure. This article provides a detailed account of the operations and designs of vacuum furnaces, discussing their pressure levels, resistance heating elements, quenching systems, work load support, pumping systems, and temperature.

Patent US4417722 Vacuum furnace for heat treatment Google Patents

Schematic diagram of the internal structure of the vertical vacuum furnace: 1 furnace lid; 2 furnace body; 3 furnace bottom; 4 electrode; 5 condensation plate; 6 observation hole; 7.

VACUUM FURNACE SYSTEM 동아셀바이오

Abstract This article discusses the principle, coil design, types and operation of a vacuum induction furnace. It describes the operation parameters that should be considered during the functioning of the induction furnace. Topics

Televac Vacuum Measurement Resources The Fredericks Company

The furnace is equipped with vacuum system, power supply system and control system. There are two kinds of vacuum induction melting furnace, intermittent and semi continuous, which can be established or horizontal. The important problem to be considered in the structure design of vacuum induction melting furnace is to avoid vacuum discharge.